Originally known as the American National Building, 9595 Wilshire Boulevard in Beverly Hills just received a brand-new curtainwall system that automatically adjusts to changes in sunlight. As the project’s historic preservation consultant, Chattel worked closely with the owner, architect and construction team to ensure the rehabilitation project conformed with the Secretary’s Standards. This project exemplifies how historic buildings can be successfully rehabilitated to align with modern building codes and enhance sustainable building performance.

Designed by architects Langdon & Wilson in the Corporate International style, the building was completed in 1972 and stands prominently at the intersection of Wilshire Boulevard, Dayton Way, and Camden Drive in the Golden Triangle. The building is a rectangular 10-story mid-rise commercial office building with ground-floor retail, a promenade plaza, and multi-level subterranean parking. The property consists of a poured-in-place concrete frame building with upper floors characterized by a distinctive exoskeleton-like grid with a bronze glass and anodized aluminum curtainwall with precast concrete panels at the roof penthouse. A 2006 historic resources survey identified 9595 Wilshire Boulevard as a contributor to a potential California Register-eligible historic district comprised of Post-World War II commercial buildings, generally along Wilshire Boulevard.

In 2021, the project was initially driven by an effort to reposition the building by upgrading the curtainwall for aesthetic and energy-efficiency. While studying the proposed rehabilitation of the exterior, the project team found two safety issues that needed to be addressed: the lack of fire separation between floors at the curtainwall and the structural soundness of the existing curtainwall system that was originally “stick-built.” The project retained the distinctive grid and replaced the entire existing curtainwall system with “smart” glass produced by manufacturer View, Inc. for its ability to transition from clear to a darker tint based on sunlight levels throughout the day. New fireproofing was also installed between each floor level and affirmatively connect the new unitized panels to the floor system. The project team also included owner representative Avison Young, project architects HLW, structural engineer KPFF, general contractor BNBuilders, and glazing subcontractor Azurelite.

The entire existing curtainwall system above grade was replaced. A key priority in the design was to maintain the facade’s original rhythm while slightly altering the inset distance of the curtainwall from the face of the concrete frame. The new painted aluminum brake metal is approximately twice the original width to accommodate an insulated glazed unit for improved energy efficiency and also for compliance with current structural codes. Chattel worked closely with the project team to ensure the new “stack-joint” and anchor attachment to the floor structure would retain most of the inset.

Historically, the vision glass, spandrel glass, and brake metal were very close to the same color, a dark bronze with brown undertones to achieve a monochromatic appearance. Chattel provided design recommendations for the new brake metal and spandrel glass colors to compliment the amber tones of the new vision glass that was only available in a single color and appears slightly more green than the original. The “smart” glass dimming technology eliminated the need for the previously used interior film and shading treatments, creating a more consistent appearance from the exterior while improving energy performance. The building’s concrete frame was also repainted with Chattel providing recommendations on color to closely match available sealant colors.

Although the alternating pattern of vision and spandrel glass remains prevalent in the façade today, the height of the spandrel glass was shortened and the vision glass was elongated, which emphasizes verticality while maintaining the historic design. Additionally, interior knee walls in each office were removed allowing for floor-to-ceiling vision glass. The full-height glass and cutting-edge technology were important aspects of the repositioning and make the building more marketable to potential new tenants.

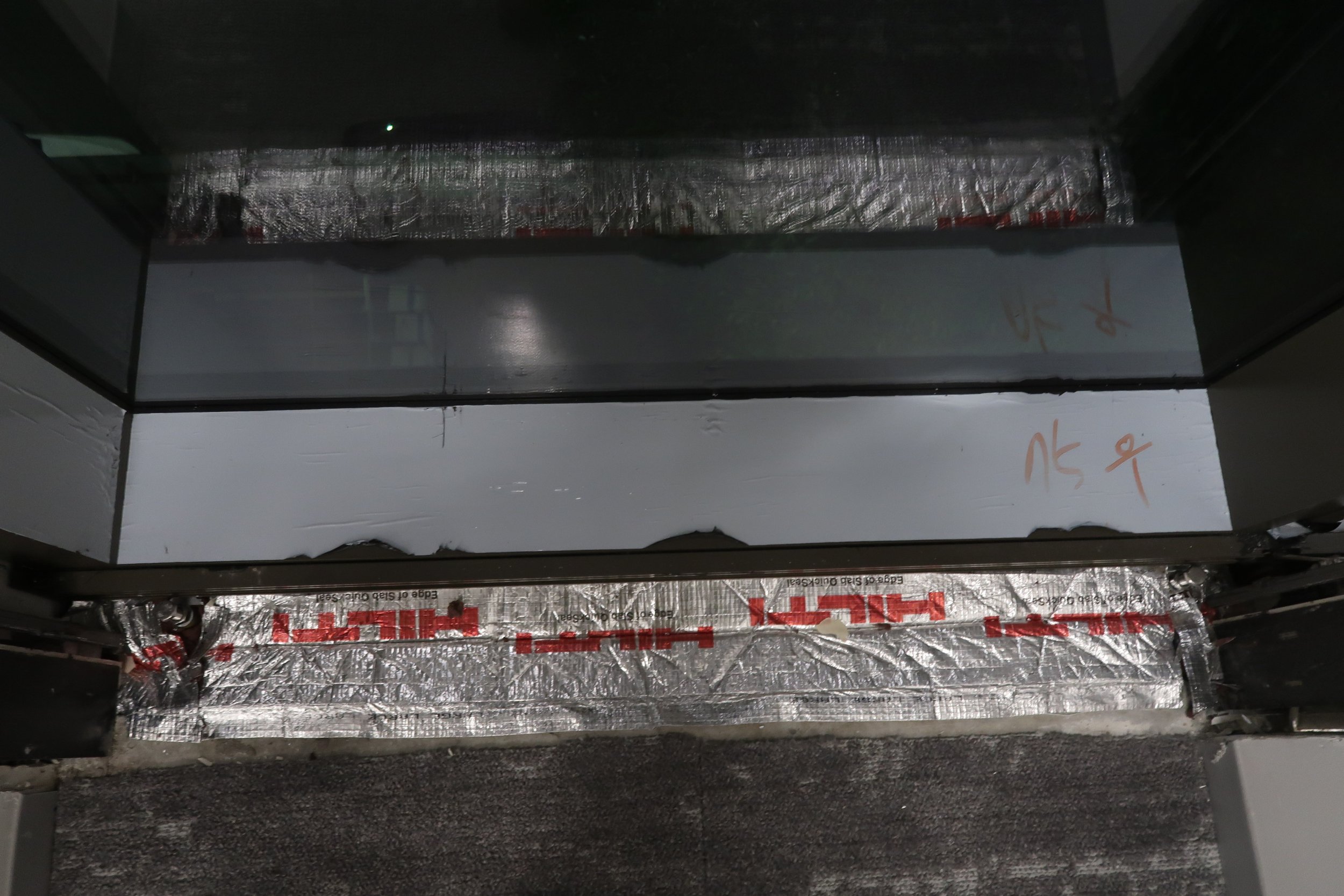

One of the logistical constraints of the project was that the building remained fully occupied during construction. This required the project team to preassemble the vision and spandrel glass panes within the aluminum brake metal frames, creating a “unitized panel.” The panels were staged and stored on temporary scaffolding that spanned each elevation above the first floor. During installation, the existing 1970s vision and spandrel glass with brake metal frame were first removed. The unitized panels were lifted one at a time using a temporary suspension mechanism mounted to the building parapet. Roof davits supported a swing deck, on which workers installed the panels to the new systems attachment. The unitized panels were installed in each grid bay three floors at a time from about 6:00 pm - 12:00 am when the wind was calm. Workers at the interior of the building assisted with installation of the unitized panels. Following installation of the unitized panels, fire-resistant insulation was installed between floors from the interior. Telephone equipment rooms were repurposed to house View Intelligence breaker boxes that run the system.